Types of non-contact level measurement available

When considering the use of a non-contact sensor for water level measurement applications, two technologies are currently prominent and readily available in the market place – Ultrasonic and Radar. Both technologies have their advantages and disadvantages, which we will outline below.

Firstly we will explain how ultrasonic technology works…

Ultrasonic non-contact level measurement

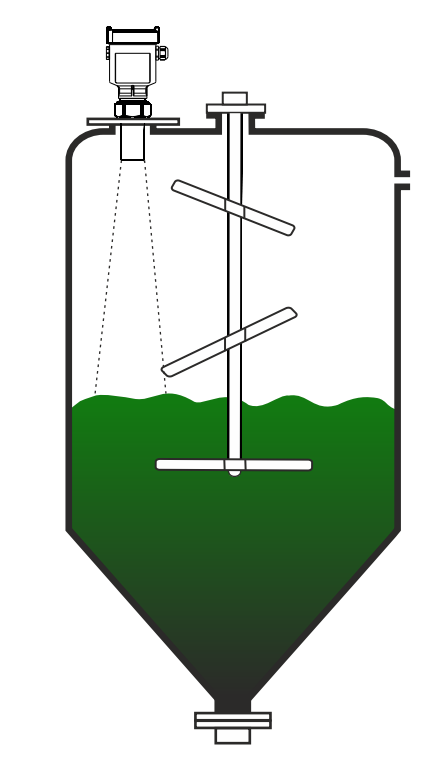

Ultrasonic measurement sensors are mounted above the water (open channel applications) or on top of the tank (contained applications).

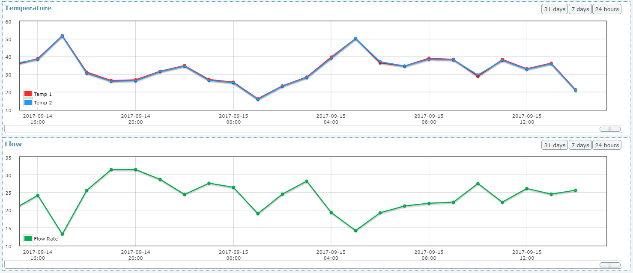

Measurement Principle: The sensor head emits an ultrasonic pulsed sound signal towards the liquid being measured, which then bounces back like an echo from the surface of the media. The sensor head then calculates the time elapsed between pulse emission and reception (Time of Flight) using filtering algorithms to generate a measurement which is proportionate to the level measurement in the channel, tank or silo. This happens many times every second to provide continuous and accurate level measurements.

Advantages

Ultrasonic level transmitters are generally lower cost when compared with a comparable radar solution. They are easy to install and program as many models feature an integral or removable display which allows the sensor to be set up whilst installed on a tank or above the open channel. With most models it is also possible to program in tank or channel shape data-points for enhanced volume calculations.

These devices are non-contacting so are not susceptible to fouling, greatly reducing maintenance when compared with a traditional contacting sensor alternative. Being a non-contact solution also means that the sensor is not susceptible to any changes in the characteristics of the fluid. However changes in air temperature will usually occur, so the on-board temperature measurement and compensation found in most models will ensure that the sensor adjusts it’s measurement for a change in the sound speed of air to ensure that accuracy levels are maintained

Disadvantages

If used in the correct application the disadvantages of ultrasonic are few. However there are applications where ultrasonic level performance can be compromised. They always need a medium and cannot propagate through Vacuum, which is a disadvantage of using Ultrasonic Transmitters for Level measurements on Vessels that operate on very low pressures. Also, sound waves are prone to attenuation depending on the medium. Whereas, Radar sensors use Electromagnetic waves which possess a Field of Energy which makes them travel through Vacuum, even without a medium.

The following conditions are examples of problematic applications for ultrasonic level measurement

-Heavy vapours

-Steam

-Foam

-Obstructions in the signal path

-Temperature effects from direct sunlight

For applications where heavy vapours, steam or foam are present we would advise the use of a radar sensor over ultrasonic technologies. Please see the radar section below.

As the ultrasonic principle relies on clean transmission and collection of the signal, anything which could potentially affect its’ path could compromise the measurement and then cause inaccuracies.

Although these situations are problematic it does not mean that they preclude the use of this technology. As an example the patented echo profile technology in our range allows for obstructions in the measurement path to be ignored as a false echo.

Another potentially negative effect on the ultrasonic principle is the exposure of the sensor to direct sunlight. Most ultrasonic transmitters and sensors have a built-in temperature sensor for air sound-speed compensation and if the ultrasonic sensor is exposed to direct sunlight this can cause the sensor to become warmer than the ambient air around the sensor. This in turn can lead to the sensor incorrectly compensating for air temperature and inaccuracies to occur in the level measurement

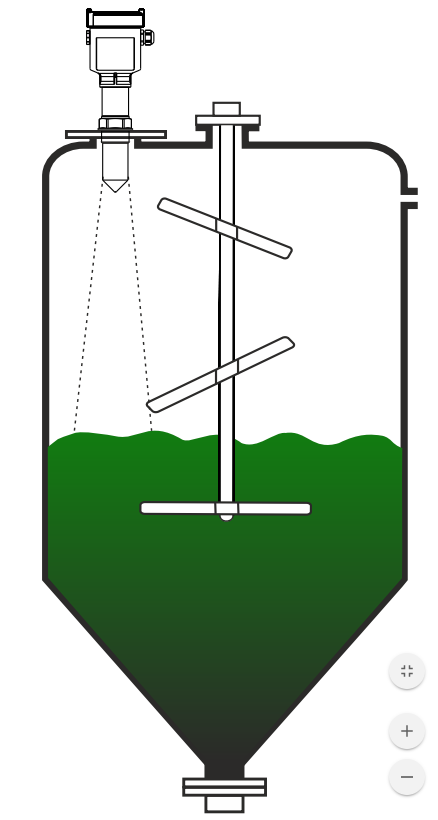

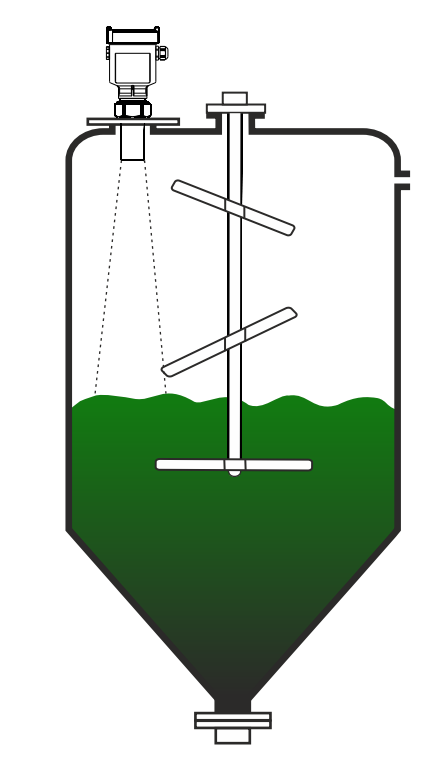

Radar non-contact level measurement

Radar measurement sensors are mounted above the water (open channel applications) or on top of the tank (contained applications). Measurement Principle: Radar, by contrast to Ultrasonic, works not with sound waves, but with electromagnetic waves. This is the key difference. Like ultrasonic types, the waves bounce off of objects and travel at a known speed (much faster than ultrasonic waves), but they react differently to certain materials. There is a different set of variables that affects how well a radar sensor operates.

Advantages

Radar sensors have a shorter dead band than their Ultrasonic equivalents (a minimum distance they have to be sited above the liquids surface.) They are also higher precision than ultrasonic models.

Unlike ultrasonic sensors, radar is much less affected by temperature, improving consistency and accuracy. Radar is also well suited for specialty applications, such as working in a vacuum, or in higher pressures (as long as the housing can handle it). Radar sensors trump ultrasonic as soon as foam, vapours, powder, dust, or uneven surfaces are introduced to the measurement environment equation, although perfect operation is not guaranteed.

They are easy to install and program as many models feature an integral or removable display which allows the sensor to be set up whilst installed on a tank or above the open channel. With most models it is also possible to program in tank or channel shape data-points for enhanced volume calculations.

These devices are non-contacting so are not susceptible to fouling, greatly reducing maintenance when compared with a traditional contacting sensor alternative. Being a non-contact solution also means that the sensor is not susceptible to any changes in the characteristics of the fluid.

Disadvantages

In general, radar transmitters are more expensive (but can handle more difficult applications), tend to have longer maximum ranges, and often have wider beam angles than ultrasonic transmitters. If used in the correct application the disadvantages of ultrasonic are few. However there are applications where ultrasonic level performance can be compromised.

The following conditions are examples of problematic applications for radar level measurement

-Domed top tanks – some radars can’t take mounting in the centre of a domed top – the parabolic effect of the dome gives them problems.

-Foam and turbulence of the media can present challenges for both technologies, especially ultrasonic (guided-wave radar may be a good choice in such cases).

-Radar’s main limitation is found in the dielectric of the material it is measuring. Low dielectrics (good insulators, poor conductors like hydrocarbons) can be problematic for radar.

-Temperature effects from direct sunlight (although not as significant as ultrasonic)

-Radar models are still higher cost than directly equivalent ultrasonic models, although the prices are coming down as the popularity of this technology and its inherent benefits rises.