Tank Cloud is perfect for a single remote tank, or an entire tank farm. We’ve got it covered, no matter what the situation.

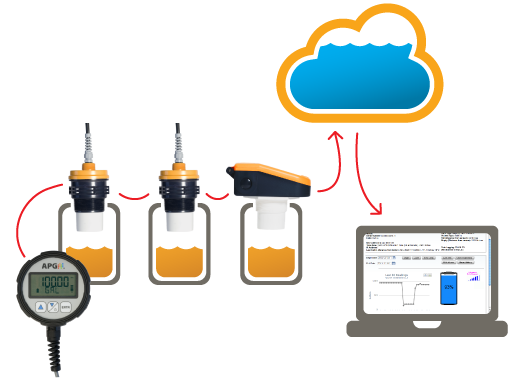

Our Tank Cloud master level sensors connect directly to the Internet for single tank applications. They also use Modbus to connect up to 10 slave sensors for tank farm applications.

Modbus is simply a communication protocol that the sensors use to pass data to the master sensors and then to the Internet for your viewing pleasure. It also makes wiring as inexpensive as it possibly can be, reducing the amount of cable needed and simplifying the wiring for easy installation.

Tank Cloud sensors can be daisy chained together for fast and inexpensive wiring. There are also a few other features designed to save you time and money – like Power Over Ethernet, that can power up to 6 sensors with the right Ethernet switch.

The sensors can be programmed remotely – so once the sensors are on the tanks, powered up, and connected you can walk away and do the rest from your office.

Features:

Adding Tank Cloud to your tanks will save you money in two critical ways:

♦ You’ll stop wasting time on the expensive task of checking remote tank levels. Enjoy tank level data at your fingertips.

♦ You’ll instantly know about expected and unexpected events. Receive an instant alert of tank empties and refills, including theft.

Stop wasting your time on level checking. This pulls your productive personnel off–task, and often costs you a lot of time and fuel to get on location. If you manage your own remote tanks, this is a major sticking point – causing a bottleneck to productivity, risk of injury, and is rarely executed with exactness.

If you collect from or refill remote tanks, you can improve your customer service dramatically, optimise collection and delivery routes, and (once optimised) service more customers with the same trucks. Relying on algorithms, or other forecasting techniques, to guess when the tank needs attention, is essentially rolling the dice.

Not only can you log-in to our secure servers at any time to see your tank level data, but you can leverage two critical tools to give your tank managers the critical information they need at exactly the right time.

Stay In The Know With Remote Tank Level Alarms

Remote monitoring is much more powerful when the right people can be notified of tank conditions at the right time. Tank Cloud’s remote tank level alarms do exactly this.

Send key personnel an automatic text message or email when tanks meet your pre-defined level condition. Give them the tool they need to respond appropriately to the routine tasks of servicing tanks, the emergency of a pending overfill, or to theft.

Tank Cloud sensors have a few different types of alarms. Local alarms can be initiated by sensor trip points and are completely user defined. Remote alarms are configured at our secure data portal at levelandflow.com.

Remote alarms will notify you when a tank is ready to be serviced – either picked up or refilled. They can even alert you to potentially unauthorised access events, such as theft. Creative uses of remote and local alarms include the initiating of a surveillance camera when tank contents are removed rapidly.

Perhaps the best part about our remote tank level alarms is that they’re completely user defined – meaning you can set them up to tell you about any tank level condition. Tank Cloud gives you the flexibility and control to set up alarms that match how you do business.

Crunch The Numbers With Tank Level Data Logging

Adding data logging to your Tank Cloud remote tank level monitoring will give you the information you need to make important long-term decisions.

Specifically, data logging will help you with the following:

♦ Tell you how and when your resources are used

♦ Give you production/usage trends

♦ Provide a record of your collections and deliveries

Understanding how your resources are used, and specifically when, is invaluable as you grow your business and plan for the busy seasons of the year. It’s one thing to have experience in your industry; it’s another to have the numbers in front of you. Optimising your business is a lot easier when you have the data to back up your decisions.

It also helps to monitor trends of production and/or usage. For inventory managers, this tool tells your purchasing department when and how much to buy. For distributors, this gives you greater insight into demand, and helps you offer amazing customer service. For collection services, this helps you understand your customer’s production rates and allows you to plan ahead.

Our data logging service will keep up to three years of data on a per sensor basis. This gives you the flexibility to pick and choose which tanks need data logging the most, and scale the solution to your exact needs. You can export the data into your favourite spreadsheet format for number crunching fun!

Applications:

Digital pressure gauges are an important part of any process that uses pressurised vessels or lines. They serve a vital safety tools to control pressure, and they help you keep your equipment running smoothly. When used right, pressure gauges are one of the most valuable instruments you can have.

Tank Cloud is an awesome solution for the right applications. It excels for most people who need to monitor tank levels in remotely located tanks. Our sensors work very well for most types of liquids, even many harsh chemicals, and our line up of sensors is continually growing.

In the past, we have had great success with a few types of applications:

♦ Tank Collection Services – Any business who is charged with emptying tanks throughout a region when they fill up.

♦ Bulk Liquid Distributors – Any distributor who transports bulk liquids and wants to help customers manage their liquids. Often a valuable service that generates revenue.

♦ Inventory Managers – Any business that manages its own bulk liquid inventory with dispersed tanks – either regionally dispersed, or in facilities spread throughout the nation or world.

Tank Collection Services

A great example of a tank collection service is used oil recycling companies. These businesses visit either restaurants or auto shops (depending on the oil in question) and remove the used oil for recycling. Often, the collection service buys the oil from the establishment and then resells it to re–refineries.

Instead of guessing when their customer’s tanks are ready for service, and often getting burned by either a lower–than–expected tank level or random theft events, these businesses are able to actively plan their routes and optimize their collections with Tank Cloud.

One national oil recycler has virtually eliminated waste and increased productivity and profitability. Our customer is now able to take on more customers with their existing assets – maximizing their ROI on their fleet investments. In addition, with the higher accuracy of Tank Cloud sensors, they can provide an accurate account of oil collected to their many customers – giving them the peace of mind that they’re getting a good deal from the collector.

Similarly, Oil & Gas companies that collect crude oil, condensate, and wastewater from distant production tanks benefit from knowing ahead of time the exact level of the tank.

Bulk Liquid Distributors

The distribution of bulk liquids depends on clear communication and a bit of forecasting. Many distributor customers have a difficult time with both communicating inventory and forecasting future need. Tank Cloud helps in both instances with real time tank level information, alarms, and data logging.

One of our customers distributes agricultural chemicals to dairies throughout the West country. Miscommunication between the dairy farmer and the distributor often resulted in over–ordering and unhappy customers.

So our customer stepped in to help dairy farmers better manage their inventory needs and provide just–in–time deliveries. The service was a new source of revenue for the company, and helped distributors and customers work together.

Inventory Managers

If you’ve ever tried to keep track of tank levels in different locations, you’ll understand how difficult it can be – especially as we ask fewer employees to take on more responsibility.

This was the case forthe Department of Transportation. Employees found that managing their inventory of liquid de-icer was a constant challenge. Remote tanks were placed strategically to maximise statewide coverage. However, without sensors and manpower truck drivers were left estimating inventory levels.

Orders were commonly too late or too big. When too much was delivered, the council was responsible for the entire order.

Tank Cloud sensors give the state employees the information they need to stay on top of the inventory and save taxpayer’s money for more important uses.

Another customer in the industrial laundry and uniform wanted to know their chemical inventory levels in a few hundred locations nationwide. In addition, they wanted to improve safety by keeping employees and chemical distributor reps off of the tanks. Tank Cloud was the perfect solution to address both inventory tracking and safety concerns.

The Bottom Line

Our customers are optimizing their business, saving money, and generating new revenue everyday by using Tank Cloud to get a handle on their remote tanks. The fact of the matter is, if you manage remote tanks, you’re losing money every day you wait.

APG level monitoring products are available from Bell Flow Systems Ltd in the UK

contact us at sales@bellflowsystems.co.uk