Accuron Cartridge-insert, open ended pipe flow meters

to fit nominal diameters 4″ – 24″

The successful measurement of low flows in partially full pipes and open channels has never been easily accomplished. Problems have ranged from questionable theory to real maintenance issues encompassing fouled sensors, sediment and plugging. The “point velocity” and “line velocity” theories that imply a velocity measured on the fluid surface or near the pipe wall can be substituted for the average velocity throughout the cross-section of the pipe have always been significantly challenged. In addition, flow sensors that sit in the invert of the pipe or hang from the top have made installation difficult, while providing a place for rags and other debris to accumulate. The accuracy of these single technology flow meters are only consistent within a specific or prescribed range of conditions. If conditions change, the stated accuracy ratings are no longer valid.

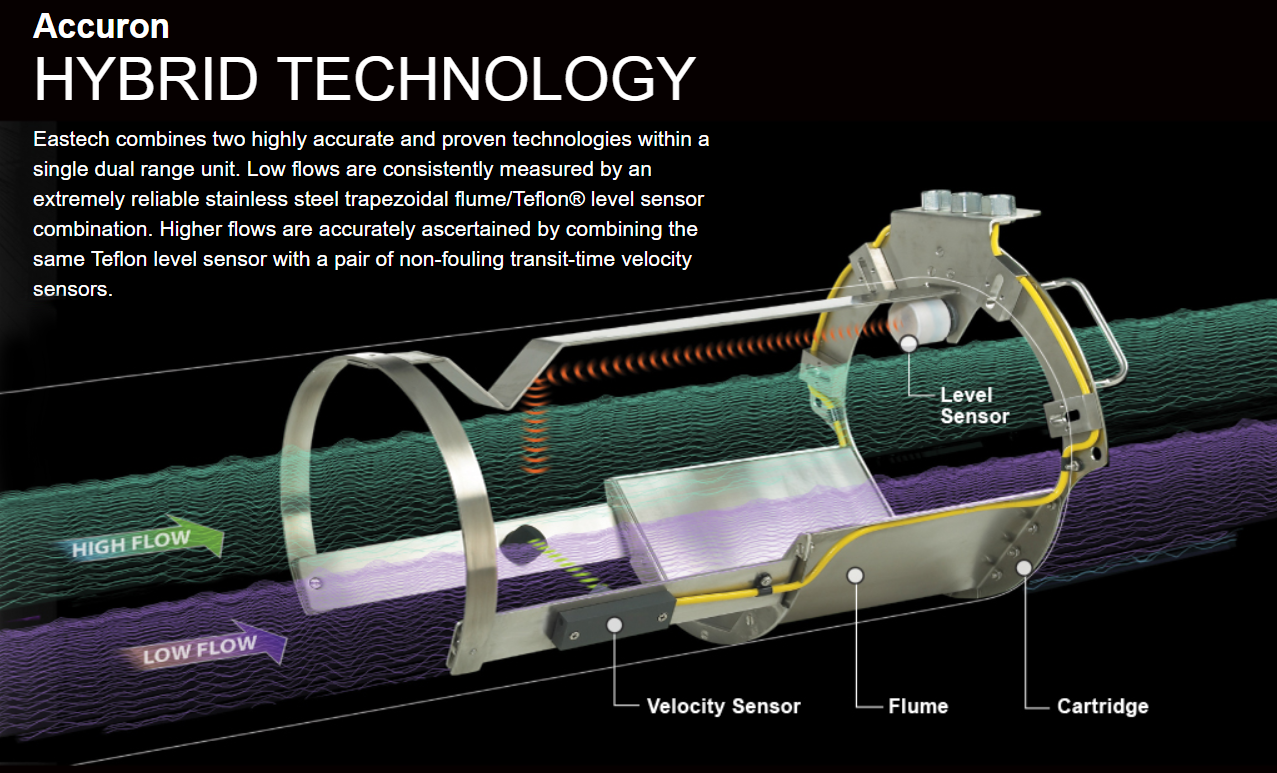

A new solution…. Accuron Hybrid Technology Cartridge Meters combine two distinct technologies in order to achieve maximum efficiency for monitoring of such flow under all conditions.

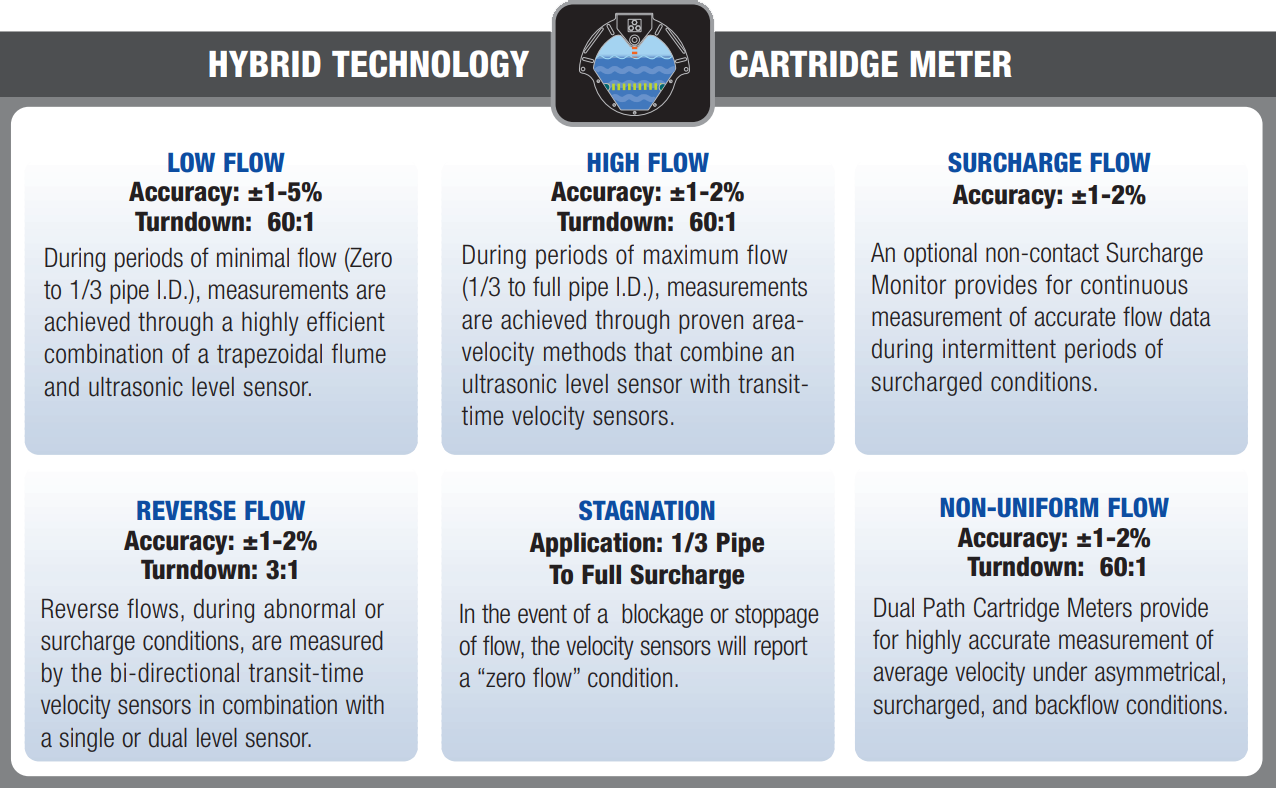

The Cartridge Meter is the first open channel flow meter to utilise hybrid technology. The new technology combines a stainless steel trapezoidal flume and Teflon level sensor combination for low flow applications with the highly accurate and non-fouling transit-time chordal velocity method for high flow applications. This new hybrid technology system allows for precise and highly accurate flow measurement during extremely low flows, high flows, flood events, reverse flows, stagnation and non-uniform hydraulic profiles.

High Performance under all conditions

During periods of minimal flow (Zero to 1/3 pipe diameter), The Accuron measures flow within its’ low operating range by utilizing the highly efficient combination of a trapezoidal flume and ultrasonic level sensor. Calibrated accuracy is ±3-5% of actual rate at a turndown: 60:1

During periods of maximum flow (1/3 to full pipe diameter). The Accuron measures flow within its high operating range by utilizing an extremely accurate area-velocity system that combines an ultrasonic level sensor with a pair of transit-time velocity sensors.

The Accuron Cartridge Meter comes with the assurance that each critical component will remain perfectly aligned during its installation plus operate free from the ongoing costs of repetitive maintenance. Transit-time chordal measurement is the most viable technique for predicting average velocity. It provides for detection of chordal velocity across the entire path of the fluid being measured.

OPERATING BENEFITS:

|

|

|

|

| 30 Minute Installation Time A stainless Cartridge, pre-sized for its specific application, arrives at the job site as a fully integrated unit. Every component is factory precision aligned, calibrated and programmed in strict accordance to customer supplied operating specifications. |

Maintenance Free Operation By utilizing “above the flow” ultrasonic level sensors and non-fouling velocity sensors, the Cartridge Meter remains free from the ongoing problems of sediment build-up, fouled sensors and accumulated debris. |

Data Logging Software Package Qtrend is an Excel Workbook Flow Data Graphing Package specifically designed to interface with every Cartridge Meter. It incorporates specific formulas capable of charting and displaying all of the data collected by the meter’s onboard logger. |

Flow Lab Accuracy Traceability

Prior to field shipment, each Cartridge Meter is NIST traceable tested, calibrated and certified at Eastech’s Flow Metrology Laboratory under the identical size and flow conditions specified for its ultimate application. |

Cost Benefits

Accuracy and cost efficiency is guaranteed by providing the end user with a pre-engineered field ready system designed for “out of the box” installation as opposed to the traditional solution. A single cartridge, pre-sized for its specific application, arrives at the job site as a fully integrated unit, requiring only 30 minutes for installation. Every component is factory precision aligned, calibrated and programmed in strict accordance to customer supplied operating specifications.

Engineering and plant personnel may now specify an extremely reliable and cost efficient system to monitor and measure flow in a single assembly. The Accuron Cartridge Meter shifts the responsibility of installed accuracy from the field to the factory. The added labour and expense of field programming, precise sensor alignment and costly flume installation is totally eliminated.

Guaranteed Accuracy

Prior to field shipment, each Accuron cartridge Meter is NIST traceable tested, calibrated and certified at the factory’s Flow Metrology Laboratory under the identical size and flow conditions specified for its ultimate application.

Maintenance Free

The risk and expense associated with repetitive confined space entry due to fouled submerged sensor problems is eliminated by utilizing an “above the flow stream” submersible Teflon level sensor. The trapezoidal flume’s flat straight through bottom permits the flume to pass debris quite readily and reduces the problem of sediment build-up up-stream of the flume and the cartridge’s transit time velocity sensors are designed to prevent the accumulation of rags, branches and similar debris from interfering with the performance of the transducers.

Why choose a Cartridge flow meter….. get the details here

See these products on our website here>>>