- Flow Meters By Type

- Flow Meters by Application

- Chemical Flow Meters

- Compressed Air Flow Meters

- Electricity Flow Meters

- Fuel Flow Meters

- Gas Flow Meters

- Hazardous Area Flow Meters

- Heat Flow Meters

- Hygienic Flow Meters

- Hydraulic Flow Meters

- Low Flow Meters

- Non Invasive Flow Meters

- Oil Flow Meters

- Open Channel Flow Meters

- Steam Flow Meters

- Water Flow Meters

- Displays and Data Logging

- Process Sensors

- Fuel & Oil Transfer

- Environmental Monitoring

- Calibration Services

- Flow Meter Hire

Coriolis Mass Flow Meters

Coriolis Mass Flow Meter for mass measurement of fluids

The Coriolis RCT 1000 enables the measurement of mass and volume flow as well as density, temperature and concentration (PID Control) with a single measuring instrument. Typical applications for these models are the dosing of biocides and additives as well as high-precision fuel supply to burners in power plants where an important increase in efficiency is achieved through direct fuel mass flow measurement. This range is also well-proven for lime milk density measurement as another specialist application.

In the chemistry and petrochemistry industries it is ideal for filling or dosing oils, solvents and chemicals. It measures online mass and volume flow, as well as density, concentration, pressure and temperature of a wide variety of fluids.

In the pulp and paper industry the Coriolis principle flow meter sets the standards in colour and coating kitchens and is perfect for the measurement of expensive chemicals and for air content measurement around the head box. These meters are especially suited for the precise measurement of high viscosity fluids whilst maintaining an extremely wide turndown ratio.

Measuring Principle

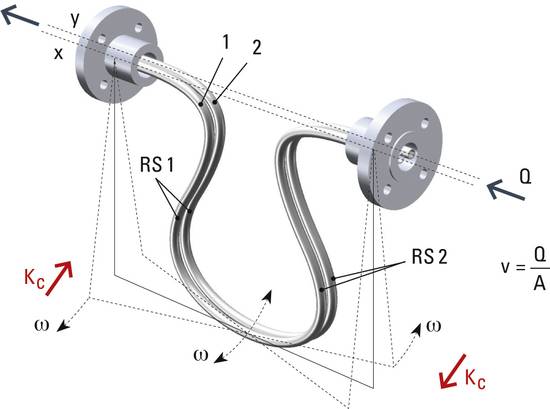

The Coriolis mass flow meter is based on the physical principle that a force , known as 'Coriolis force' acts on any mass that is moving towards or away from the point of rotation within a rotating system. The symmetrically arranged measuring tubes labelled 1 and 2 are vibrated against each other in the X and Y axis. The limbs RS 1 and RS 2 of the measuring tubes oscillate on a circular segment in case of zero flow.