Categories

Product Selector

News

- Feb 12, 2024 Coriolis Mass Flow Meters - ATEX Certified CG range of high performance ATEX approved Coriolis flow meters for Liquids and Gases. ... Read more

- Jan 2, 2024 TBQSe Digital Gas Flow Meters with built-in EVC These turbine flow meters are ideal for commercial and industrial applications for measuring natural gas in pipe sizes from DN25 up to DN150.... Read more

- Oct 17, 2023 ATEX Approval for Oil Interface Meters Model H.OIL Portable oil water interface meter from Heron Instruments receives much anticipated ATEX approval for European market... Read more

Mixing It Up! Macnaught MX Meters

Mixing It Up! - Fuel Additive Ratio Measurement Using Macnaught MX Meters

A large UK fuel refinery approached Bell Flow Systems to propose a solution to providing accurate ratio control for a new fuel additive system.

The installation transferred bio-diesel from a 1,000,000 litre tank through a loading arm gantry in to 36,000 litre fuel tankers. The refinery needed the additive to be injected in to the line at a very specific ratio. The additive would need to be pumped from a local IBC container and injected into the main fuelling pipe under pressure. The ratio had to remain fixed at 1 part additive to 640 parts biodiesel in order to perform its intended purpose.

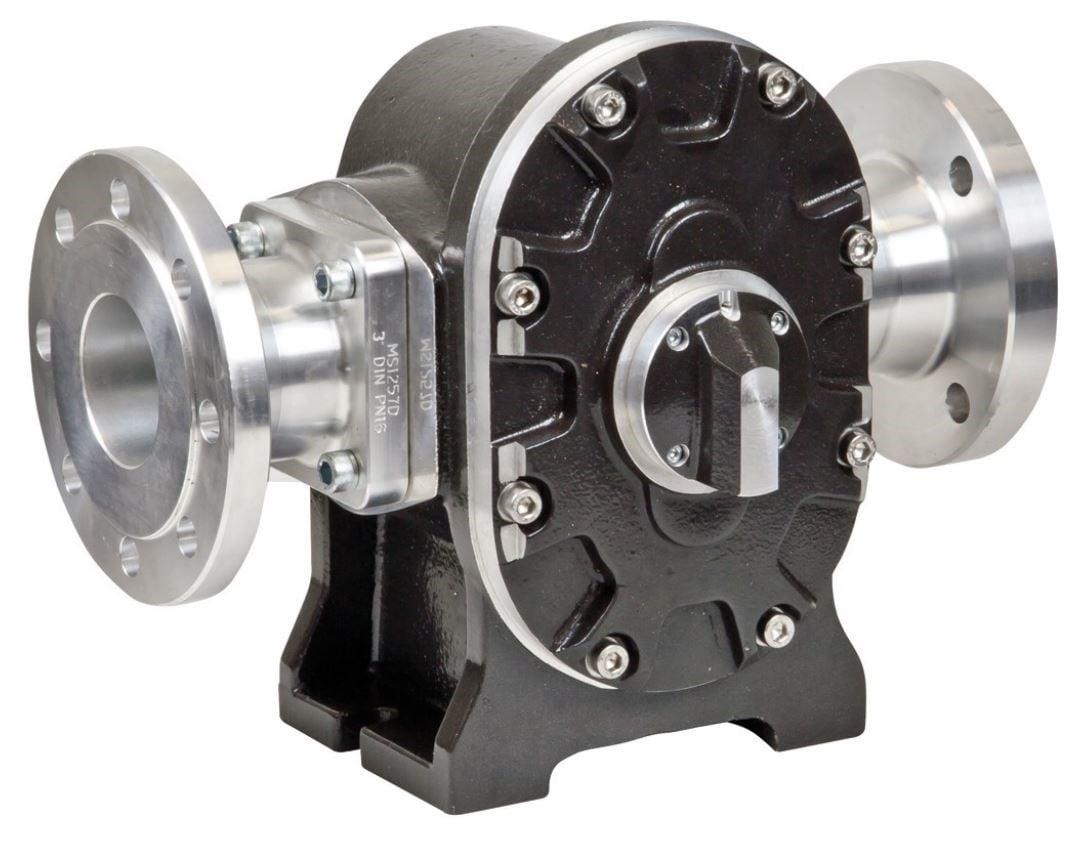

Bell Flow Systems supplied two Macnaught MX oval gear type meters sized DN80 and DN15 for the bio-diesel and additive respectively. These would provide the high accuracy and repeatability needed for this application and would also negate the requirement for a damper on the additive line - usually needed to calm pulsating flow from the dosing pump. Positive displacement flow meters can cope with pulsating flows and other challenging flow profiles where other principles may not.

The digital signal outputs from the two Macnaught meters would then go into a Fluidwell F124 ratio controller, which is the brains of the operation.

The F124 ratio controller has the ability to control the dosing pump speed via its 4-20mA analogue output. Whilst in operation the user will enter the required ratio, i.e. 1:640 in this instance, and the F124 would monitor the flows from both flow meters. It would maintain the correct ratio by controlling the dosing pumps output of the additive.

Click to view the full range of Macnaught oval gear meters >>