Categories

Product Selector

News

- Feb 12, 2024 Coriolis Mass Flow Meters - ATEX Certified CG range of high performance ATEX approved Coriolis flow meters for Liquids and Gases. ... Read more

- Jan 2, 2024 TBQSe Digital Gas Flow Meters with built-in EVC These turbine flow meters are ideal for commercial and industrial applications for measuring natural gas in pipe sizes from DN25 up to DN150.... Read more

- Oct 17, 2023 ATEX Approval for Oil Interface Meters Model H.OIL Portable oil water interface meter from Heron Instruments receives much anticipated ATEX approval for European market... Read more

MTM Turbine Gas Flow Meters, Custody Transfer Approved MID/OIML

MTM TURBINE GAS METERS - MID & OIML Approved

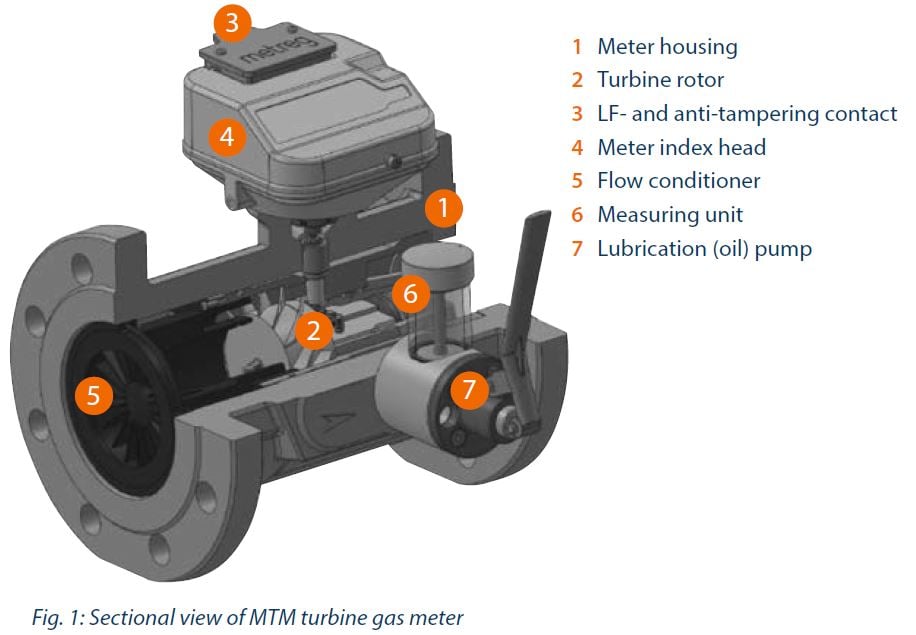

MTM Turbine gas flow meters are now available in the UK exclusively from Bell Flow Systems. Manufactured by Metreg Technologies who offer a complete product range for fiscal and non-fiscal gas flow meters for industrial and commercial applications.

MTM Flanged Gas Turbine Flow Meters have Approvals to MID Class 1 (DIN EN 12261:2002) OIML R137-1&2: 2012, PED (PED 97/23/EG). The MTM Gas Meter is suitable for installation in hazardous areas of Category 2 (Zone 1) II 2 G c IIC T4 X. MTM Gas turbine flow meters are ideal for commercial metering and custody transfer measurement applications, suitable for measuring natural gas in pipe sizes from DN50 up to DN300 and larger. The flexible measuring cartridge of the

MTM turbine meter is exchangeable for different pressure housing designs. It can be calibrated in each diameter size to the different G-ratings. Operating pressures up to 100 bar and a volume flow rates of 5 m3/h up to 6500 m3/h depending on the different meter sizes at operating conditions. Available with a choice of flanges, these robust flow meter models have an Aluminium rotor and body made of anodized high strength Aluminium, Carbon Steel or a welded steel construction dependant on size and spec. A Low frequency pulse is included as standard with HF and multiple pulse options for remote monitoring, data recording and linking with Building Management Systems (BMS) as well as with our MID approved (EVC) gas volume correctors and Telemetry devices.

Design Strength

The gas flow is narrowed via an annular cross section and then is accelerated and directed onto the smooth-running Aluminium rotor. The number of rotations is proportional to the traversed gas volume, the frequency of rotations is proportional to the actual gas flow. The rotation of the rotor is connected to a speed-reducing gear train and transmitted by a magnetic coupling to the adjustable roller counter mechanism. The lifetime durability of the MTM turbine meter is very stable due to the large dimensioned high precision ball bearings manufactured in Germany, along with the high precision machining of the body and all moving parts on state of the art machine centres . After machining, all Aluminium parts, especially the turbine wheel, are hard anodized for reduced friction and higher resistance to mechanical wear and tear or chemical attack.

Low Pressure Loss

The pressure loss of the MTM turbine meter is minimized through a dynamically optimized inlet diffusor, very low manufacturing tolerances and high precision, low friction ball bearings. The optimized flow conditions allow a minimal straight inlet pipe of 2 DN for low level flow disturbances and only 2 DN additional straight inlet pipe length under severely disturbed flow profile according to OIML standards. MTM turbine meter housings are manufactured on a standard basis with raised face (RF) flanges according to DIN/EN 1092-1 or ANSI B 16.5 for class 150/300/600 with a maximum operating pressure of 100 bar/ 10 MPa.

Key features

• Meter size G 65 to G 4000

• Flow rates from 5 to 6500 m3/h

• Nominal sizes from DN 50 to DN 300 (2“ to 12“)

• Pressure class PN 10 to PN 100 and ANSI Class 150, 300 and 600

• Measuring range 1:20, optional 1:30 depending on operating conditions

• Meter housing made of anodized high strength Aluminum, Carbon Steel

or a welded steel construction

• Permanent lubrication of ball bearings up to 16 bar and DN 50 - DN 150 as standard,

optional manual lubrication by means of oil pump

• Manual lubrication by means of oil pump as standard for sizes DN 200 - DN 300

and for all MTM turbine meters with operating pressure > 16 bar

• Index head by default made of engineering UV stabilized polymer material,

optional made of Aluminum

• Rotating counter (355 °)

• Compact installation by straight inlet pipe ≥ 2DN and outlet pipe ≥ 1 DN

with low level perturbations. In case of high level perturbations an additional straight

inlet pipe of 2DN is necessary

• Horizontal and vertical mounting positions possible

• Approvals according to MID (2004/22/EG), OIML, PED (PED 97/23/EG), ATEX

Bell Flow Systems mail@bellflowsystems.co.uk or call 01280 817304 for more information on the Metreg gas meter ranges.