Categories

Product Selector

News

- Feb 12, 2024 Coriolis Mass Flow Meters - ATEX Certified CG range of high performance ATEX approved Coriolis flow meters for Liquids and Gases. ... Read more

- Jan 2, 2024 TBQSe Digital Gas Flow Meters with built-in EVC These turbine flow meters are ideal for commercial and industrial applications for measuring natural gas in pipe sizes from DN25 up to DN150.... Read more

- Oct 17, 2023 ATEX Approval for Oil Interface Meters Model H.OIL Portable oil water interface meter from Heron Instruments receives much anticipated ATEX approval for European market... Read more

New Oval Gear Flow Meter Catalogue from Badger Meter

Badger Meters full range of Oval Gear flow meters can now all be seen in one place. A wide range of sizes, materials, displays and component options are available.

Download the New brochure here: ![]()

Oval gear meters are volumetric meters and are most suited for liquids with a viscosity up to 1.000 mPas. (special models up to 500.000 mPas.). Due to the robust nature of this particular flow measurement technology, the meters can be used where other types of measurement technologies are not suited.. The meters handle very viscous or highly corrosive fluids. They have been designed for a variety of chemical applications including petroleum-based fluids, water solutions and any other liquid compatible with the materials of construction.

BENEFITS

• Flexibility of installation options (vertical installation or horizontal installation)

• Minimum number of wearable parts for long product life and easy field servicing

• Wide range of instrumentation available for control system interfacing

FEATURES

• Compact size

• High accuracy and repeatability

• Factory calibrated (stated in pulses per liter)

• Low pressure drop

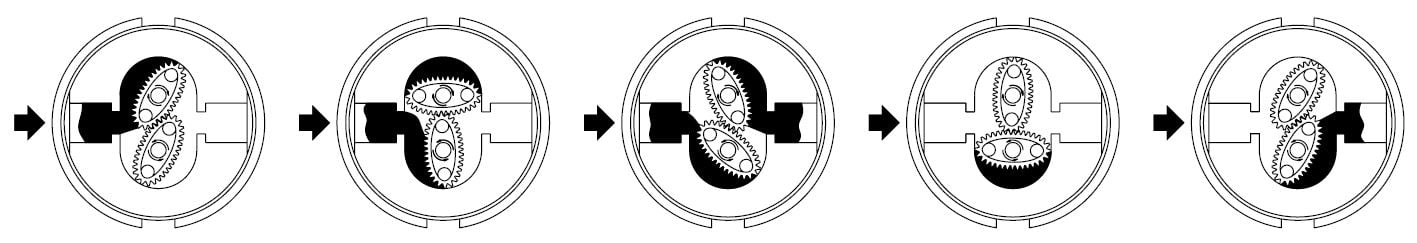

As fluid passes through the metering chamber by entering

the inlet port, it forces the internal gears to rotate and exits

through the outlet port. Each rotation of the gear displaces

a given volume of fluid. Controlled clearances between the

gears and chamber wall ensure minimum leakage. As the

gears rotate, a magnet on each end of the gear activates the

reedswitch and forward the pulses to the display or to the

pulse output.