Categories

Product Selector

News

- Apr 9, 2024 Versatile D-Series Flow Displays D-Series DIN Standard Panel mount Flow Measurement displays... Read more

- Feb 12, 2024 Coriolis Mass Flow Meters - ATEX Certified CG range of high performance ATEX approved Coriolis flow meters for Liquids and Gases. ... Read more

- Jan 2, 2024 TBQSe Digital Gas Flow Meters with built-in EVC These turbine flow meters are ideal for commercial and industrial applications for measuring natural gas in pipe sizes from DN25 up to DN150.... Read more

Zero straight runs required !! M2000 Electromagnetic Flow Meter

M2000 Mag Flow Meters can be installed without the need for upstream or downstream straight pipe runs

Whether you’re looking to reduce costs, comply with regulations or upgrade to the latest technology without significant modifications to your system, our ModMAG® M2000 Electromagnetic flow meter is an ideal choice for your unique application needs.

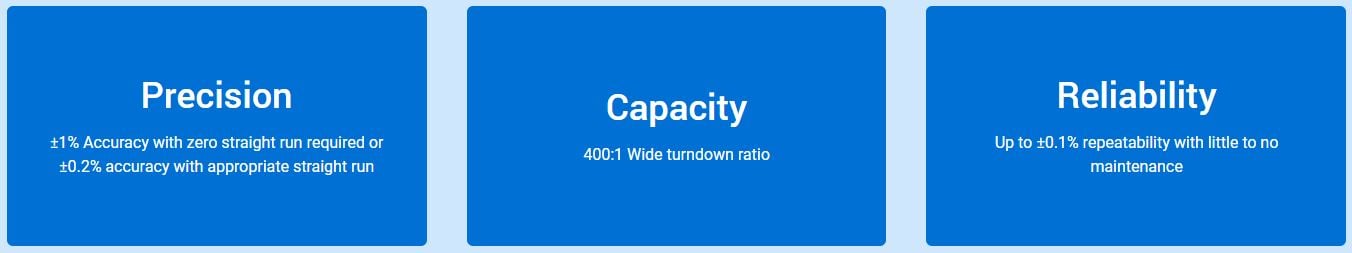

The M2000 meter is a trusted technology to measure the flow of water and conductive liquids with zero straight run required. Its zero straight run performance has been validated to OIML/MID standards, providing accuracies of ±1% with zero straight run up or down or ±0.2% with required straight run. This meter supports both accuracy ratings out of the box, without needing firmware adjustments.

Chief and facility engineers, facility managers and controls and plumbing contractors can install the M2000 meter without significantly modifying their applications, saving time and installation costs. Additional benefits include:

♦ Low Maintenance: Promotes confidence by having a measurement device that is highly repeatable up to ±0.1% with little to no maintenance required.

♦ Precision: Provides accurate measurements up to ±0.2% with required straight run or ±1% with zero straight run requirements for a wide variety of outputs to connect to your system. With precise data, commercial and industrial facility operators can reduce energy expenses and optimize both hydronic systems and building cost allocation.

♦ Full-Bore Design: Features a full-bore design, which means that there is no size reduction resulting in undesirable pressure drops.

Typical application= Hot/Chilled Water Systems

♦ Dependable: Facility operators must have a reliable means of staging chillers and boilers and maintaining efficient operations based on fluctuating chilled/hot water demand. To do so, they need to deploy a precise and dependable flow measurement solution. The M2000 meter is a full-bore instrument with virtually no pressure drop, which eliminates energy loss within the hydronic system. The meter has no moving parts to clog or fail over time and delivers consistent, high-accuracy liquid flow measurements.