Categories

Product Selector

News

- Apr 9, 2024 Versatile D-Series Flow Displays D-Series DIN Standard Panel mount Flow Measurement displays... Read more

- Feb 12, 2024 Coriolis Mass Flow Meters - ATEX Certified CG range of high performance ATEX approved Coriolis flow meters for Liquids and Gases. ... Read more

- Jan 2, 2024 TBQSe Digital Gas Flow Meters with built-in EVC These turbine flow meters are ideal for commercial and industrial applications for measuring natural gas in pipe sizes from DN25 up to DN150.... Read more

IOG Hygienic Flow Meters have FDA conformance

IOG Positive Displacement Gear Flow Meters - Laser welded and polished Tri-clamp connections

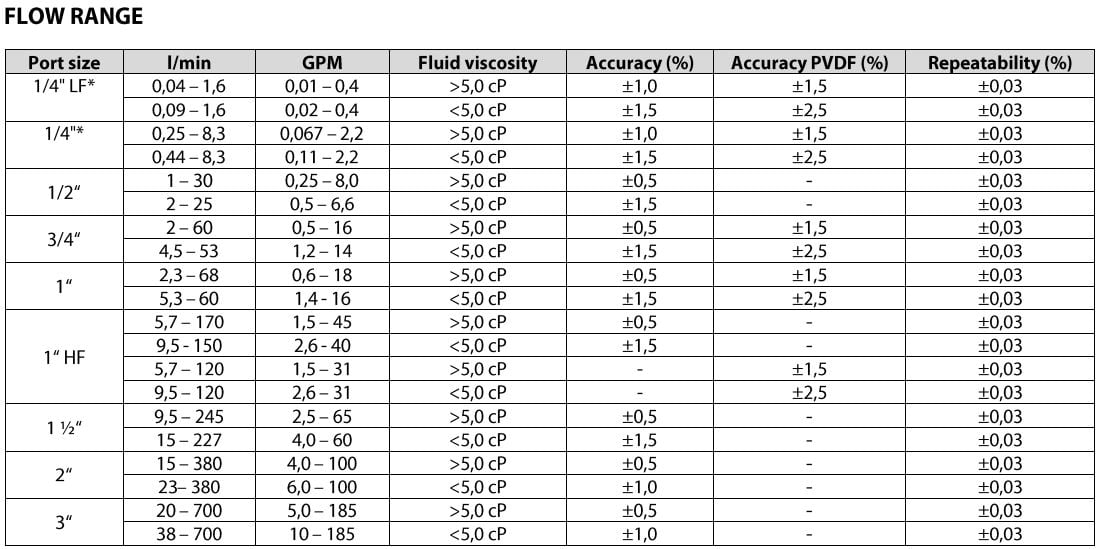

Badger Meter IOG flow meters, available in 1/4…3 inch sizes, provide an effective solution for optimizing process operations—even in very low-flow environments—enabling users to match the meter size to their application for utmost accuracy. The meters deliver precise flow measurements to eliminate waste, and with low pressure drop, have minimal impact on system energy requirements to move liquids.

The IOG line features a compact size allowing for either vertical or horizontal installation into confined areas where space is at a premium. Plus, these meters do not require a straight run of pipe or flow conditioning.

Oval Gear flow meters are very accurate and extremely repeatable, making them ideal for batching, mixing and dosing. These volumetric type meters and are best suited for liquids with a viscosity up to 5.000 mPas. (special models up to 1.000.000 mPas are available.)

See options for HV- High Viscosity model >1000 Centipoise

Oval Gear explanation- As fluid passes through the metering chamber by entering the inlet port, it forces the internal gears to rotate and exits through the outlet port. Each rotation of the gear displaces a given volume of fluid. Controlled clearances between the gears and chamber wall insure minimum leakage. As the gears rotate, a magnet on each end of the gear activates the reed switch and forwards the pulses to the display or raw pulse output.

Features

• Local / Remote displays available or Pulsed output signal

• High Accuracy and Repeatability

• ATEX Approval options

• FDA Conformity

• Model sizes 1/4" to 3"

• Low Pressure Loss design

• Insensitive to pulsating flow eg. AODD pumps

• No need for flow conditioning upstream or downstream (straight pipe lengths)

• High Viscosity option

• Horizontal or Vertical orientation

• Individually Calibrated